The U.S. Army has come under scrutiny for mismanagement of equipment stockpiles designated for U.S. Central Command (CENTCOM), as revealed in a recent audit conducted by the Department of Defense Inspector General (DOD IG). The audit highlights significant deficiencies in the maintenance and oversight of Force Provider modules, which are essential prepositioned units comprising multiple shipping containers filled with necessary materials for establishing temporary facilities.

According to the DOD IG report, the Army’s failure to effectively manage the Care of Supplies in Storage (COSIS) for these modules has raised serious concerns. The report indicated that the Integrated Logistics Support Center at the Army’s Tank-Automotive & Armaments Command (TACOM ILSC) did not adequately oversee or train contractors responsible for maintaining these critical supplies.

Failures in Equipment Maintenance

The mismanagement issues reportedly began in 2016 when the Army awarded a $23.8 million contract to an undisclosed company to maintain the Force Provider modules. In 2020, responsibility for these modules was transferred to another entity, but critical maintenance requirements were not established until April 2024. This oversight has led to numerous complaints from troops in the field, particularly regarding broken or inoperable equipment.

For instance, in 2022, several military units reported receiving Force Provider containers containing damaged tents, malfunctioning generators, and faulty laundry equipment. The report noted, “Had [name redacted] separately accounted for those items that require maintenance and required the contractor to perform maintenance at the appropriate intervals, the defective equipment would have been identified before issuance.”

One contributing factor to the mismanagement may have been confusion surrounding inspection requirements for equipment stored in various environments. During a training event in June 2024, TACOM instructed officials to elevate the Force Provider modules above the desert ground to protect them from environmental elements. Nevertheless, the actual maintenance plan lacked clear guidelines to safeguard these modules from outdoor conditions.

Training and Documentation Deficiencies

The audit further revealed a critical gap in contractor training. Proper handling of the containers is essential to preserve the equipment inside, yet the DOD IG found that the training requirements were not documented to ensure that personnel understood how to maintain the modules correctly.

With a new contractor now assuming responsibility for the Force Provider modules, there are concerns that skilled personnel may be rotated out before new staff receive adequate training. Different types of equipment necessitate varying levels of maintenance, yet the audit indicated that contractors did not track essential maintenance items, such as skid steers, under the Global Combat Support System-Army (GCSS-A).

This lack of precise accountability has serious implications, especially in operational scenarios. For example, the report mentioned that Army personnel required fully mission-capable ventilators during the COVID-19 pandemic but lacked visibility of their ventilator inventory because some were included in medical kits and not separately accounted for in GCSS-Army.

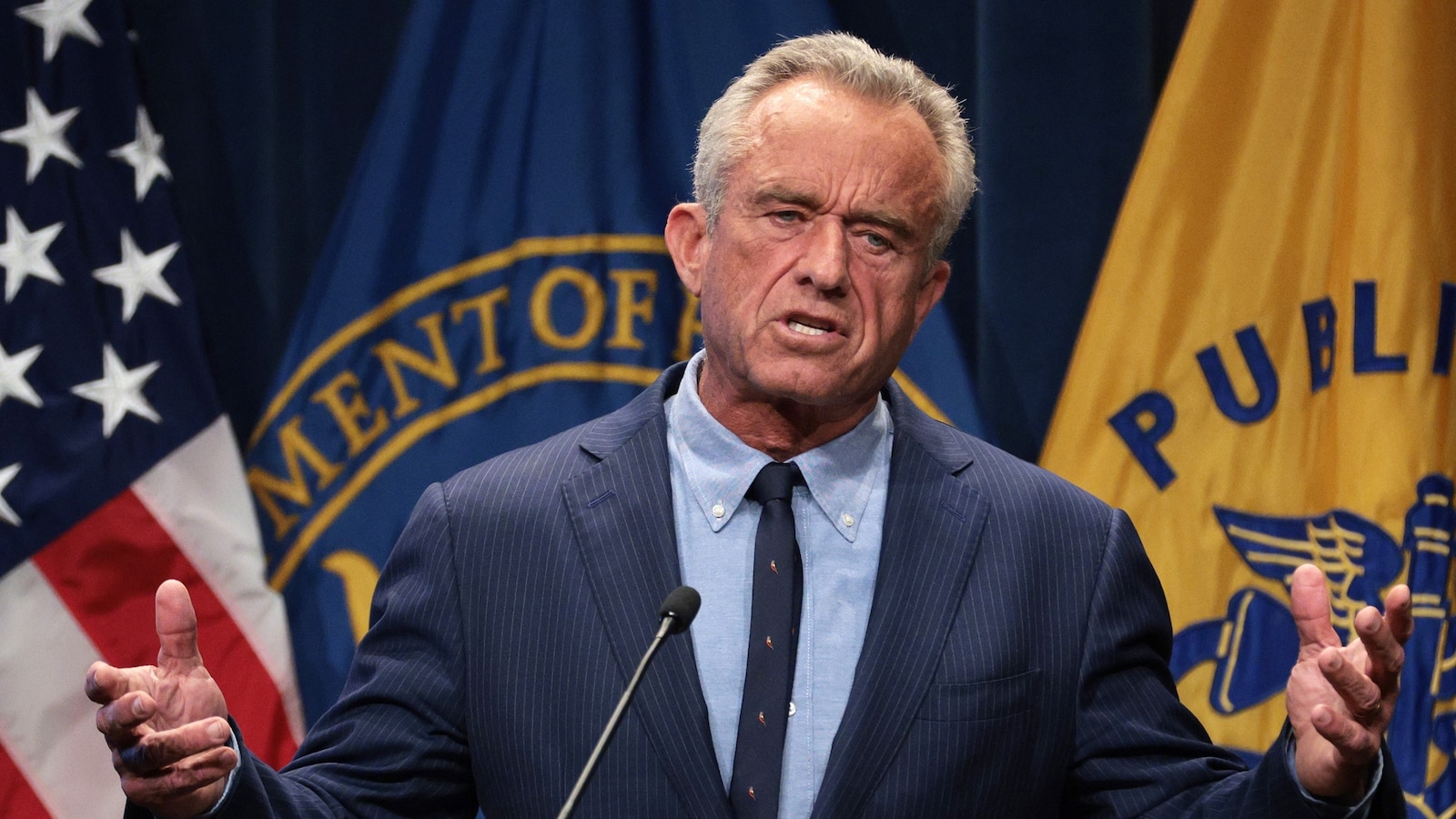

In response to these findings, the DOD IG has recommended that TACOM’s Integrated Logistics Support Center revise the 2011 Force Provider Care of Supplies in Storage plan. This revision should include specific environmental storage and maintenance guidelines for outdoor storage, definitive maintenance intervals, and clear responsibilities for training in Force Provider module maintenance.

The findings underscore the critical need for improved management and oversight in the Army’s logistics operations, particularly as U.S. forces continue to engage in diverse global missions.