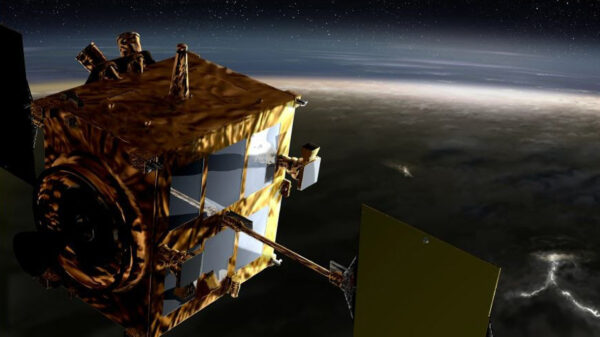

The U.S. defense industrial base is increasingly vulnerable due to its heavy reliance on materials sourced from China, according to a report by the Government Accountability Office (GAO) released on July 24, 2024. This dependency poses significant national security risks for the U.S. military as it relies on a vast network of over 200,000 suppliers for critical weapon systems and military equipment.

The GAO highlighted that the Department of Defense (DOD) utilizes the Federal Procurement Data System database to track materials and components from potentially hostile nations. However, the database currently offers “limited information about the countries of origin,” leaving a gap in transparency. Federal contractors are not contractually required to disclose the full origins of their manufacturing components, which complicates the DOD’s efforts to mitigate risks associated with foreign dependencies.

In its analysis, the GAO found that of the over 99 materials identified by the DOD as being in short supply for fiscal year 2023, none were produced domestically. Consequently, many components integral to the U.S. military’s key weapon systems are manufactured in China and other adversarial countries, raising concerns about supply chain integrity.

“These suppliers may cut off U.S. access to critical materials or provide ‘back doors’ in their technology that serve as intelligence pathways,” the GAO report stated. This concern was underscored in 2024 when China implemented export restrictions on gallium and germanium, two minerals deemed essential for military-grade electronics.

The report also cited a significant disruption in the production of the F-35 Joint Strike Fighter, which is manufactured in collaboration with several allied nations, including the United Kingdom, Canada, and Australia. Production was halted after the discovery of prohibited Chinese components, specifically magnets, in the supply chain. The prime contractor, Lockheed Martin, notified the DOD in both 2023 and 2024, leading to a temporary pause in manufacturing as the agency sought alternative suppliers.

The challenges extend beyond aircraft. The U.S. naval shipbuilding industry, particularly in submarine production, faces similar issues. The report noted that submarines require titanium casting for critical components, yet the U.S. currently lacks sufficient capacity to produce this material domestically. Presently, there is only one foundry capable of producing large titanium castings essential for certain key weapon systems.

Despite acknowledging the risks tied to foreign dependency, the DOD has not acted on GAO’s recommendations for improvements. These would include enhanced tracking of the countries of origin for critical military components. The report suggested that one potential solution could involve requiring suppliers to contractually disclose this information. Some DOD officials believe such data is readily available, while others express concerns about the potential costs and the willingness of suppliers to comply.

The findings of this report raise critical questions about the sustainability and security of the U.S. defense supply chain. As global dynamics continue to evolve, addressing these vulnerabilities could be vital for maintaining the operational readiness and security of U.S. military forces.