The automotive industry is on the brink of significant transformation as manufacturers seek to address the high costs associated with electric vehicle (EV) batteries. A notable shift is occurring towards innovative battery production methods, particularly the adoption of dry electrode manufacturing. This approach could significantly reduce energy consumption and production costs, paving the way for broader EV adoption.

According to the International Energy Agency, global sales of electric vehicles surpassed 20 percent of new car sales in 2024. Despite this growth, mass adoption remains limited due to the high costs that still plague many consumers. Major automakers, including General Motors, have responded by pausing production on certain models, signaling caution in a market that is rapidly evolving.

The core challenge lies in the cost of EV batteries, which comprise approximately 40 percent of an electric vehicle’s total price. The price of battery cells is particularly critical, as highlighted by the latest survey from BloombergNEF. The survey indicates that the manufacturing of battery cells is the primary factor determining whether an EV can be offered at a competitive price.

Understanding Battery Costs

A substantial portion of an EV battery cell’s cost—around 70 percent—stems from materials, including the active components and separators. The remaining 30 percent is attributed to manufacturing processes, as detailed by Thunder Said Energy, an energy technology consultancy based in Austin, Texas. As researchers work to improve battery chemistries, such as lithium-iron-phosphate (LFP) and nickel-manganese-cobalt (NMC), the manufacturing methods themselves have seen little innovation over the decades.

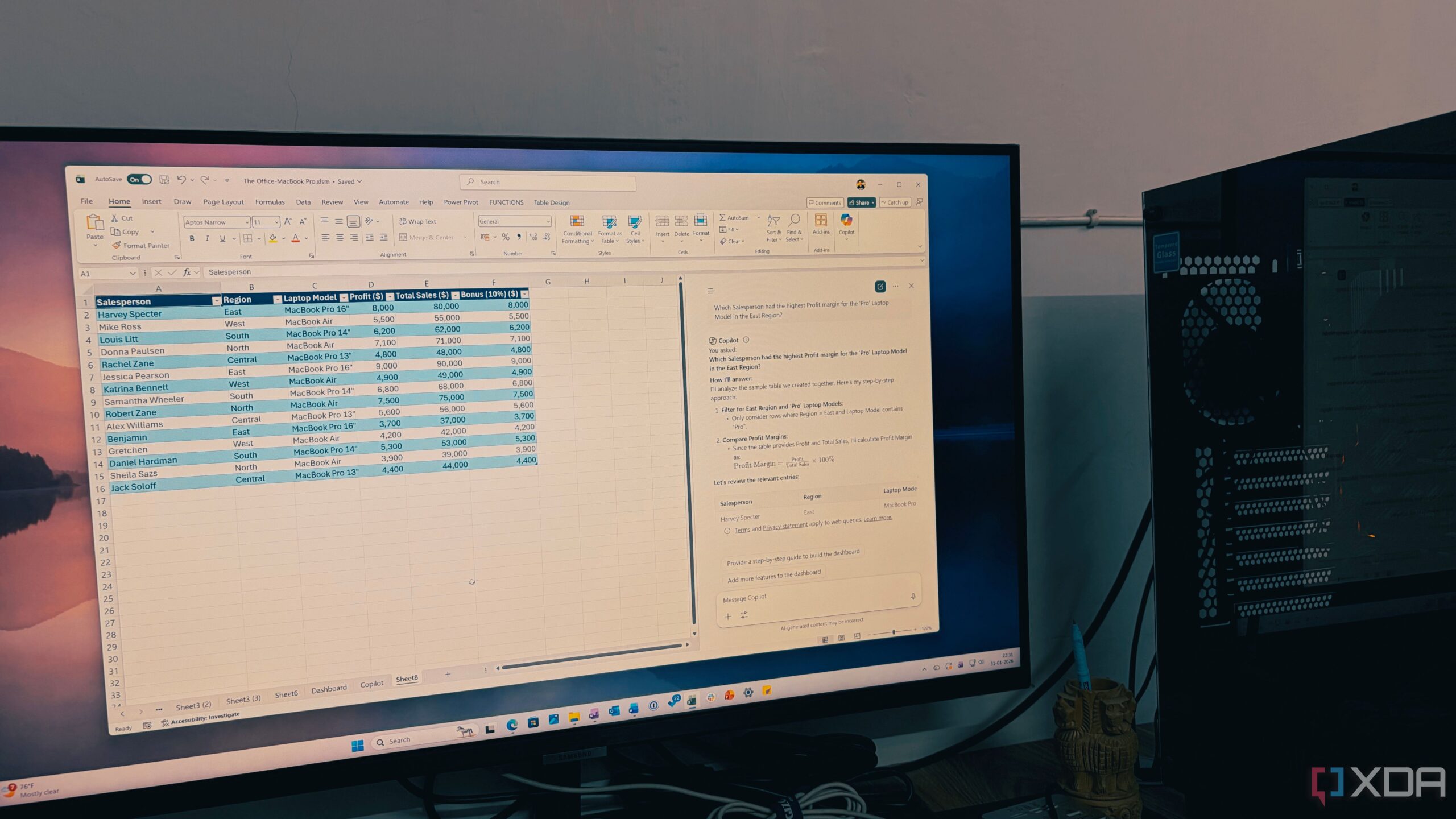

The traditional “wet-coating” process for battery cells involves mixing active powders with solvents and drying them in large industrial ovens. A single factory capable of producing 50 gigawatt-hours of battery cells—enough for approximately one million EVs—can consume as much electricity as about 40,000 homes, according to the U.S. Energy Information Administration. This method not only incurs high energy costs but also presents significant environmental challenges.

Innovations in Dry Electrode Manufacturing

This backdrop has led to a growing interest in dry electrode manufacturing, which promises to cut costs and energy use significantly. The elimination of solvents can lead to smaller factory footprints and lower environmental impact. However, achieving effective dry coating at scale presents challenges, including maintaining even distribution and strong adhesion of the materials.

“The resulting film-forming powder behaves almost like kinetic sand: granular when loose, cohesive under pressure,”

explains a representative from Anaphite, a company based in Bristol, England, which has developed a proprietary Dry Coating Precursor (DCP) technology. This method utilizes low-toxicity solvents for initial dispersion before mechanically removing the solvent, resulting in a flexible electrode layer that adheres well to its substrate. The process reportedly achieves an 85 percent reduction in energy use and up to a 40 percent reduction in production costs.

Parallel developments are occurring at Sakuù in San Jose, California. Their innovative “laser-printing” method applies dry powders directly to foils without the need for wet slurries, likening the process to “frosting a cake.” This technology not only minimizes carbon-dioxide emissions by approximately 55 percent but also allows for significant reductions in factory size and utility costs.

Both Anaphite and Sakuù represent a shift towards more sustainable and cost-effective battery manufacturing techniques. While their methods differ, the overarching goal remains the same: to create a future where battery production is more efficient and affordable.

The advancements in dry coating technology not only promise cost reductions but also enable the production of thicker electrodes. This change can lead to batteries with higher energy density, ultimately enhancing the range of electric vehicles. As these innovations take hold, the case for electrification becomes increasingly compelling.

The ongoing dry-coating revolution suggests a future where electric vehicles are not just an environmentally friendly choice but also the most practical option for consumers. With companies like Anaphite and Sakuù leading the charge, the landscape of battery production is set to transform dramatically, making clean mobility more mainstream.