A joint research team has unveiled a groundbreaking method for detecting invisible defects in semiconductor devices, achieving approximately 1,000 times higher sensitivity than current techniques. This advancement promises to enhance the performance and reliability of essential technologies, including memory chips and solar cells.

Defects, often referred to as electronic traps, can significantly disrupt electrical flow in semiconductor materials. These hidden imperfections can lead to performance degradation, impacting everything from consumer electronics to renewable energy applications. The innovative analysis method developed by the team allows for a more precise identification of these critical issues.

Collaboration Between Leading Institutions

The research was conducted by a collaboration between the National Institute of Standards and Technology (NIST) and the University of California, Berkeley. Both institutions are recognized for their contributions to semiconductor technology and material science. The findings were published in October 2023, marking a significant milestone in semiconductor research.

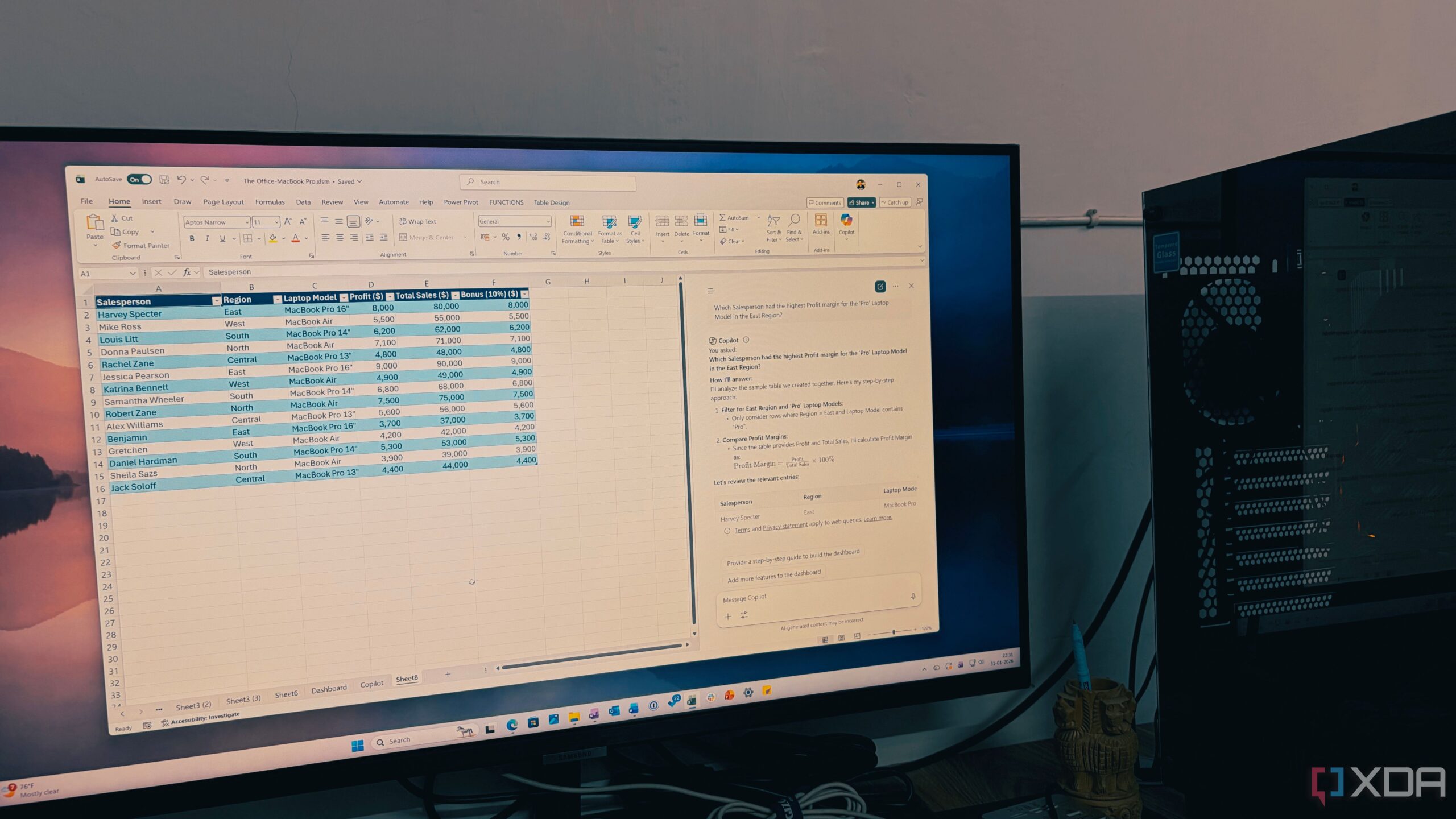

The new technique relies on advanced imaging and analysis processes, which enable researchers to visualize and quantify defects that were previously undetectable. By employing this method, the team can pinpoint specific locations within the semiconductor structure where defects occur, allowing for targeted improvements in manufacturing processes.

Implications for the Semiconductor Industry

This advancement has substantial implications for the semiconductor industry, which is experiencing unprecedented demand due to the growing reliance on digital technologies. As devices become more complex, the need for improved performance and efficiency in semiconductor materials becomes increasingly critical.

According to the research team, the ability to detect defects with such heightened sensitivity can lead to significant cost savings in production and improved product durability. This could ultimately translate to enhanced consumer experiences as electronic devices become more reliable and efficient.

The implications extend beyond consumer electronics, affecting sectors such as renewable energy. In solar cells, for instance, the detection of hidden defects can improve energy conversion efficiency, contributing to more sustainable energy solutions.

The researchers believe that the adoption of this new analysis method could set a new standard for quality assurance in semiconductor manufacturing. By integrating these advanced detection techniques into production lines, manufacturers can ensure higher quality products and reduce the risk of failures in the field.

As the semiconductor industry continues to evolve, innovations such as this one will be essential in meeting the challenges of tomorrow’s technology landscape. The research team remains optimistic about the potential applications of their findings, envisioning a future where semiconductor devices perform at their peak potential, free from the limitations imposed by hidden defects.