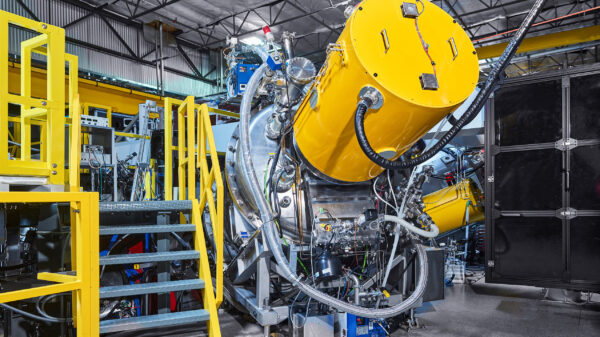

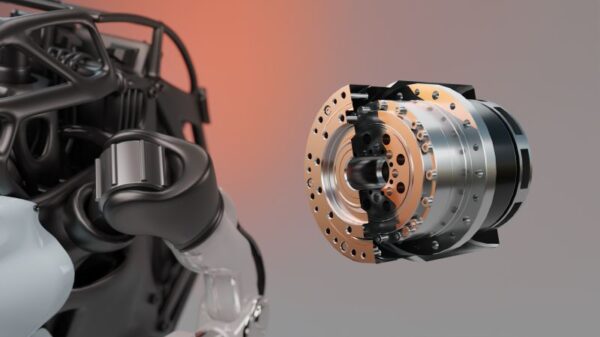

Recent advancements in artificial intelligence have led to the development of gerotor pumps that significantly outperform traditional human-engineered designs. These pumps play an essential role in automotive and hydraulic systems, primarily for oil circulation and lubrication. By optimizing the gerotor tooth profile, engineers have improved the pumps’ efficiency, enhancing their overall performance.

Gerotor pumps are known for their compact design, which allows them to deliver an excellent flow rate per rotation while maintaining high suction capabilities. Such characteristics make them invaluable in applications requiring precise lubrication and fluid transfer. The recent innovations powered by AI technology promise to elevate the effectiveness of these components further.

AI-Driven Design Enhancements

The incorporation of AI into the design process has enabled engineers to simulate countless variations of tooth profiles and geometries. This computational approach not only accelerates the design timeline but also allows for a level of optimization that was previously unattainable. According to research conducted by leading engineering firms, the AI-generated components demonstrate improvements in both efficiency and durability compared to their human-designed counterparts.

A study published in March 2024 highlights that these AI-optimized gerotor pumps can achieve a flow rate increase of up to 15% over traditional designs. This enhancement translates to better engine performance and reduced energy consumption, aligning with the automotive industry’s push towards more sustainable technologies.

Implications for the Automotive Industry

The introduction of AI-designed components is set to have a profound impact on the automotive sector. With the rising demand for efficient and environmentally friendly vehicles, manufacturers are eager to integrate these advanced gerotor pumps into their systems. As a result, the automotive industry could see a significant shift towards more innovative engineering solutions that leverage AI capabilities.

Engine lubrication and automatic transmission systems, in particular, stand to benefit from this technological leap. Improved pump performance can lead to better fuel efficiency and longer engine life, ultimately providing consumers with a more reliable and cost-effective driving experience.

The collaboration between AI technology and engineering expertise marks a pivotal moment in the evolution of automotive components. As more automotive manufacturers embrace these advancements, the landscape of vehicle design and functionality is likely to change dramatically.

In conclusion, the development of AI-optimized gerotor pumps not only enhances the performance of critical automotive systems but also paves the way for a more sustainable future in vehicle engineering. As the technology continues to evolve, its applications may extend beyond automotive uses, influencing various sectors reliant on hydraulic systems and fluid transfer solutions.