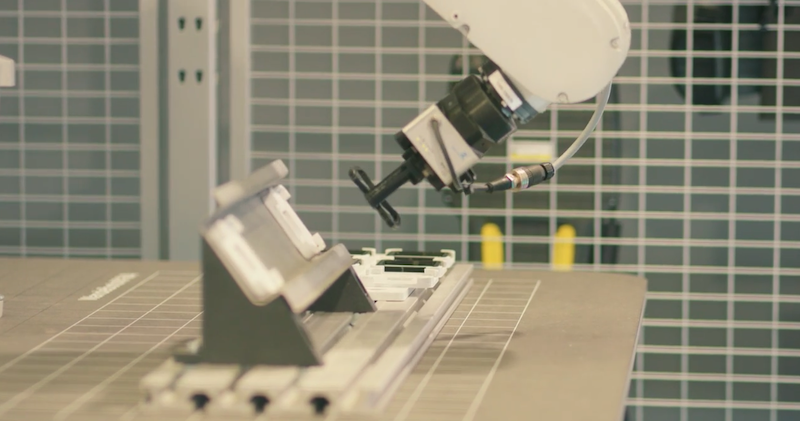

SmartRay has introduced an innovative weld inspection system, known as JOSY, at the European Industrial AI Innovation Hub located at the Skyloop in Stuttgart. This fully automated system is designed to enhance weld inspection processes through advanced artificial intelligence capabilities.

The live demonstration showcased JOSY’s hardware alongside Tool Path Generation software, developed in collaboration with both Wandelbots and Grid Dynamics. This partnership has resulted in a close-loop workflow that significantly boosts operational efficiency while also eliminating potential errors associated with manual inspections.

SmartRay’s JOSY system aims to transform the landscape of industrial welding inspections, which have traditionally relied on manual methods. By utilizing AI, the system can provide real-time feedback and analysis, allowing for quicker adjustments during the welding process. This not only streamlines production but can also lead to reduced costs and improved product quality.

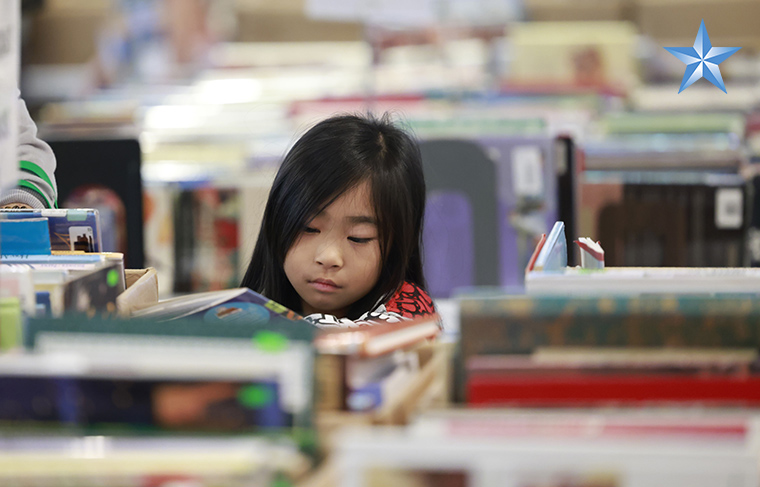

The event at the European Industrial AI Innovation Hub attracted industry leaders and experts, highlighting the growing importance of integrating AI into manufacturing processes. Attendees had the opportunity to see firsthand how the JOSY system operates, emphasizing its potential to set new standards in quality assurance.

According to SmartRay, the implementation of AI in their weld inspection technology is a significant step forward. “We are excited to demonstrate how JOSY can enhance manufacturing workflows,” said a company representative. “This technology represents a leap towards more reliable and efficient production methods.”

As industries worldwide increasingly adopt automation and AI technologies, SmartRay’s introduction of the JOSY system reflects a broader trend towards modernization in manufacturing. Companies are seeking solutions that not only improve accuracy but also adapt to the ever-evolving demands of the market.

In summary, SmartRay’s JOSY weld inspection system exemplifies the integration of innovative technology in traditional manufacturing sectors. As the industry moves forward, the capabilities demonstrated in Stuttgart may pave the way for similar advancements across various fields.