In a groundbreaking study, researchers have developed a new lubrication technique aimed at improving the machining process of the nickel-based alloy GH4169, commonly used in aerospace manufacturing. The study, led by a team from Qingdao University of Technology and Hanergy Lubrication Technology Co., Ltd., focuses on Electrostatic Atomization Minimum Quantity Lubrication (EMQL) as a solution to the challenges posed by traditional machining methods.

GH4169 is renowned for its excellent high-temperature strength, hardness, oxidation resistance, and corrosion resistance, making it essential for aeroengine components. However, machining this alloy presents significant challenges, including high milling temperatures and residual stress, which can compromise the integrity of the finished product. Traditional high-flow cutting fluids contribute to environmental pollution and have low utilization rates, while conventional Minimum Quantity Lubrication (MQL) systems suffer from issues such as uncontrollable droplet sizes and health risks associated with fine particle drift.

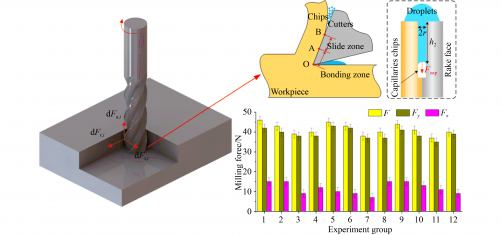

The research team, consisting of Min Yang, Hao Ma, Zhonghao Li, Jiachao Hao, Mingzheng Liu, Xin Cui, Yanbin Zhang, Zongming Zhou, Yunze Long, and Changhe Li, aimed to establish a comprehensive milling force model. This model discretizes the helical edge of the end mill into microelements, accounting for tangential, radial, and axial forces to derive the total cutting force. By conducting experiments using soybean oil as the lubrication medium, the team compared the performance of EMQL with conventional pneumatic atomization MQL techniques.

The results demonstrate that EMQL significantly enhances milling performance. The study found that EMQL reduces milling force by between 15.2% and 15.9%, surface roughness by 30.9% to 54.2%, and the friction coefficient by 55%. Additionally, the cutting specific energy decreased by 19.6%.

Key Findings and Optimization Parameters

Further investigations included orthogonal optimization experiments to evaluate the impact of various parameters such as flow rate, air pressure, voltage, incident angle, elevation angle, and target distance on milling performance. The findings indicated that air pressure had the most considerable effect on milling force and cutting specific energy, contributing 22% to the outcomes. In contrast, voltage was determined to have the greatest influence on surface roughness, with a contribution rate of 36.71%.

After analyzing the surface morphology of the workpieces and considering the environmental and health impacts related to droplet drift, the researchers identified the optimal parameter combination for the EMQL process. This combination includes a flow rate of 80 mL/h, air pressure of 0.1 MPa, voltage of 30 kV, a nozzle incident angle of 35°, elevation angle of 30°, and a target distance of 40 mm.

The study provides critical insights that could enhance the surface integrity of challenging aerospace materials during machining. The full research paper titled “Force Model in Electrostatic Atomization Minimum Quantity Lubrication Milling GH4169 and Performance Evaluation” is available for further reading at https://doi.org/10.1007/s11465-024-0800-8.

This research marks a significant step forward in aerospace manufacturing, offering a promising avenue for improved machining techniques that prioritize both performance and environmental safety.