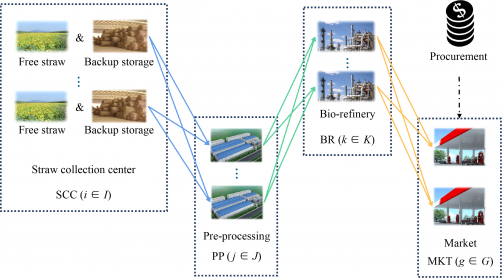

In a significant advancement for the biofuel industry, researchers from Tianjin University have introduced a new methodology for designing resilient supply chains that can effectively withstand disruptions. Their study, titled “Optimization design method for biofuel resilient supply chain considering node disruption impacts in a two-stage stochastic programming framework,” was published in Frontiers of Chemical Science & Engineering, Volume 19, Issue 6.

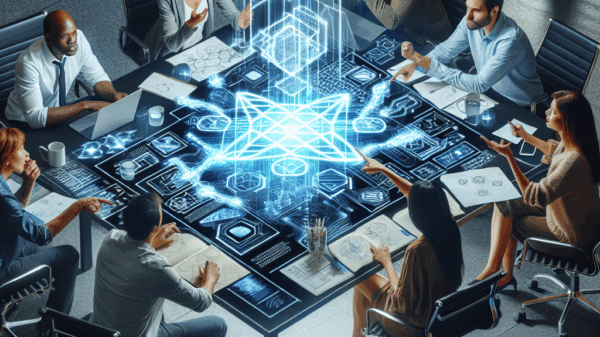

As the world becomes increasingly interconnected, biofuel supply chains are expanding in complexity and scale. Businesses are facing heightened uncertainties and a greater risk of disruptions, making it vital to develop supply chains that maintain both security and competitive edge. The researchers emphasize that existing supply chain design methods often fall short in addressing the risks associated with potential disruptions.

Innovative Index for Risk Assessment

To tackle these challenges, the study proposes an improved Node Disruption Impact Index. This index is designed with adjustable parameters that reflect cost variations within the supply chain arising from disruptions at different nodes. By identifying nodes with diverse risk levels, the index offers a robust framework for evaluating the impact of disruptions.

The adjustable parameters are particularly beneficial for supply chain enterprises, allowing them to balance economic benefits with resilience against disruptions. This flexibility is crucial for businesses operating in an environment where risk management is increasingly important.

Two-Stage Stochastic Programming Model

Furthermore, the study develops a two-stage stochastic programming model that incorporates a mechanism for addressing potential high disruption risks. This model was applied to a case study focusing on a biofuel supply chain in Guangdong Province. The results indicated that when high-risk nodes experienced interruptions, the proposed model outperformed traditional approaches in both cost efficiency and market delivery rates.

“Our findings confirm the effectiveness of this method in optimizing resilient supply chains,” the researchers noted.

This research highlights the urgent need for effective tools in the design of resilient biofuel supply chains. By offering a concrete solution to the challenges posed by disruptions, the proposed methodologies could play a critical role in enhancing the stability and efficiency of biofuel supply systems globally. For those seeking more detailed insights, the full paper is accessible at https://journal.hep.com.cn/fcse/EN/10.1007/s11705-025-2548-z.