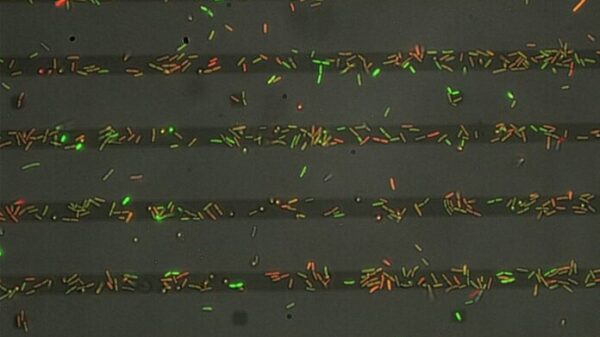

In the competitive landscape of biotechnology, New England Biolabs (NEB) is positioning itself as a leader in customized solutions for life science product development. The company recently highlighted how its Customized Solutions Team is addressing challenges faced by developers in this field. With a focus on innovation and partnership, NEB is helping companies navigate issues such as technical expertise, manufacturing scale, and regulatory compliance.

To gain insight into this initiative, John Pezza, PhD, Customized Solutions Director at NEB, and Mike Pelletier, Director of Global Operations, shared their perspectives on the expectations customers should have from a customized solutions vendor. They emphasized the importance of flexibility, operational integration, and quality assurance.

Meeting Customer Needs with Flexibility and Quality

According to John Pezza, customers should seek vendors who demonstrate a robust capacity to tailor solutions. This encompasses everything from minor adjustments in formulation to comprehensive product development. A reputable vendor can support clients throughout various stages, including early development, pilot batches, and full-scale commercial production. “A flexible vendor will also be able to support customers at every stage, with the agility to scale volume and adapt to evolving requirements,” Pezza stated.

Operational integration is another key expectation. NEB has built its customized solutions infrastructure based on rigorous internal standards honed over decades of scientific innovation. This commitment ensures that clients benefit from the same reliability that NEB applies to its own product development.

Quality assurance is paramount, especially in regulated markets. Customers can anticipate an audit-ready package that adheres to both internal quality standards and external regulations. NEB’s quality team brings extensive experience in these environments, further solidifying the company’s reliability as a partner.

Streamlining Development Timelines

Reducing lead time is essential for biotech developers. Pezza pointed out that efficient communication and process integration are critical factors. At NEB, an emphasis on open dialogue and direct access to scientific staff helps keep custom product development aligned with customer expectations.

The company’s vertically integrated model reduces handoffs and maintains control over critical process steps, thus streamlining timelines. This operational efficiency is crucial, whether clients are transitioning from research and development or gearing up for commercial launches.

Mike Pelletier elaborated on the foresight that NEB employs to prepare for future needs. “As a privately held company, NEB has the flexibility to invest in infrastructure and technology without being constrained by short-term returns,” he noted. This proactive approach has resulted in significant expansions, including a 40,000-square-foot GMP-grade production facility established prior to the pandemic, which allowed NEB to supply essential reagents for vaccine development.

In 2023, NEB further expanded by adding an additional 100,000 square feet to its production infrastructure, enhancing capacity to support a diverse range of applications and volumes. The company also opened a 30,000-square-foot lyophilization facility to meet the growing demand for room temperature-stable molecular biology products.

These developments are part of NEB’s broader strategy, which includes ongoing investment in sustainable practices and support for basic research.

Building Trust and Transparency

For prospective clients looking to evaluate their custom solutions vendor, Pelletier suggests visiting NEB’s facilities. These visits provide a firsthand look at operations and allow potential partners to meet the team behind the products. “Our team’s enthusiasm and commitment to customer satisfaction are best experienced face-to-face,” he mentioned.

NEB encourages customers to schedule audits in advance, viewing them as opportunities to strengthen relationships. The company’s facilities are designed to meet the highest quality standards, ensuring transparency and trust.

Many clients are often surprised by the comprehensive nature of NEB’s offerings. The company provides an end-to-end experience that includes collaborative development, custom formulation, and a wide array of fill sizes and packaging options. This level of integration is rare in the industry and positions NEB to respond effectively to unique supply chain needs.

The organization’s ability to scale operations has been demonstrated during the pandemic, where it successfully supported heightened demand without interruption. NEB has established a reputation for excellence, with a quality team experienced in navigating the complexities of regulated markets.

The depth of NEB’s capabilities is also attributed to the institutional knowledge of its employees. The company enjoys exceptionally low employee turnover, which promotes continuity and accumulated expertise. Many scientific staff members involved in product development also participate in customization efforts, fostering trust and accelerating problem-solving.

As NEB continues to drive innovation in the biotechnology sector, its Customized Solutions Team is poised to meet the evolving needs of customers, ensuring that they are equipped with the tools necessary for success in a rapidly changing environment.