A recent project titled “pISSStream” has captured attention for utilizing NASA’s official telemetry stream to track the current level of the urine tank on the International Space Station (ISS). This lighthearted initiative highlights not only the innovative spirit of space engineering but also raises intriguing questions about how liquid levels are measured in a microgravity environment.

Understanding liquid measurement in space requires a fundamental shift in perspective. Without a defined “up” or “down,” traditional concepts of liquid levels become obsolete. Instead, surface tension and capillary action dictate fluid behavior. Astronauts have famously demonstrated this by manipulating water droplets in microgravity, which take on spherical shapes due to surface tension.

During the Apollo missions, NASA employed sophisticated techniques to monitor liquid levels. High-speed cameras inside fuel tanks provided insights into fluid dynamics during flight. Similar methods are still in use today, with companies like SpaceX employing advanced monitoring systems to ensure propellant delivery to rocket engines.

Engineering Challenges in Liquid Measurement

Settling propellants in a spacecraft tank involves carefully managing the liquid’s position to ensure engines receive fuel when needed. Ullage motors play a crucial role in this process, providing the necessary acceleration to move propellants toward the outlets of their tanks. The Saturn V rockets from the Apollo era utilized multiple solid-fuel ullage motors to achieve this, ensuring that the fuel remained available for engine operation.

Despite the engineering efforts, measuring the volume of remaining propellants is often simplified through flow sensors rather than direct liquid level measurements. This method, known as bookkeeping or flow accounting, tracks fuel consumption based on the flow rate and initial volume. For the ISS, this approach is reversed for the urine tank, where the volume resets with each resupply mission.

Advanced Measurement Techniques

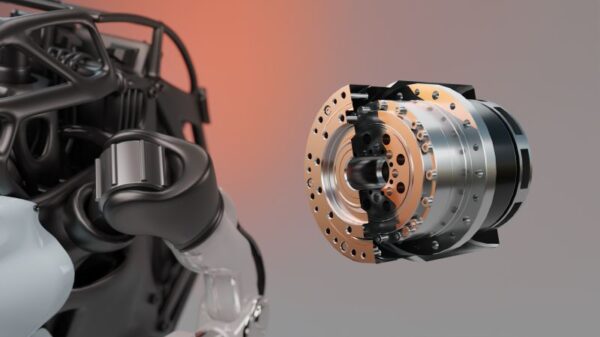

Various gauging methods have been developed to ensure accurate propellant monitoring during space missions. The Propellant Utilization Gauging Subsystem (PUGS), used during the Apollo missions, relied on capacitive probes that measured the capacitance across the probes to determine liquid levels. This technique was vital for managing fuel and oxidizer levels during flight.

Recent innovations in gauging methods include Electrical Capacitance Volume Tomography (ECVT) and Radio Frequency Mass Gauging (RFMG). ECVT utilizes an array of electrodes to create a map of liquid distribution within a tank. This method is particularly effective for mixed-phase fluids that can float in discrete blobs.

RFMG, which involves sending radio frequency signals into a tank and analyzing the reflections, has been tested on the ISS. The method was utilized in February 2024 during the lunar landing of Intuitive Machines’ IM-1 lander. Despite the lander tipping over upon landing, RFMG proved essential in confirming the accuracy of cryogenic fuel levels.

As space missions become more frequent and ambitious, understanding liquid behavior in microgravity will remain a vital area of research. Projects like “pISSStream” serve not just to entertain but to remind us of the complexities and innovations within space engineering.