A collaboration between engineering seniors at the University of Wisconsin-Stout and Ashley Furniture has led to the development of an innovative prototype for a nonstandard pallet stacker. This project aims to enhance efficiency and safety in material handling, addressing critical needs in the furniture industry.

The prototype, engineered by students Chase Rodewald, Riley Stiehl, Zachary Morgan, and Luke Mertens, showcases their technical skills and creativity. The students utilized advanced design software, SolidWorks, to create a digital model before assembling the physical version. This hands-on experience not only allowed them to apply their academic knowledge but also provided vital insights into real-world engineering challenges.

Enhancing Efficiency and Safety

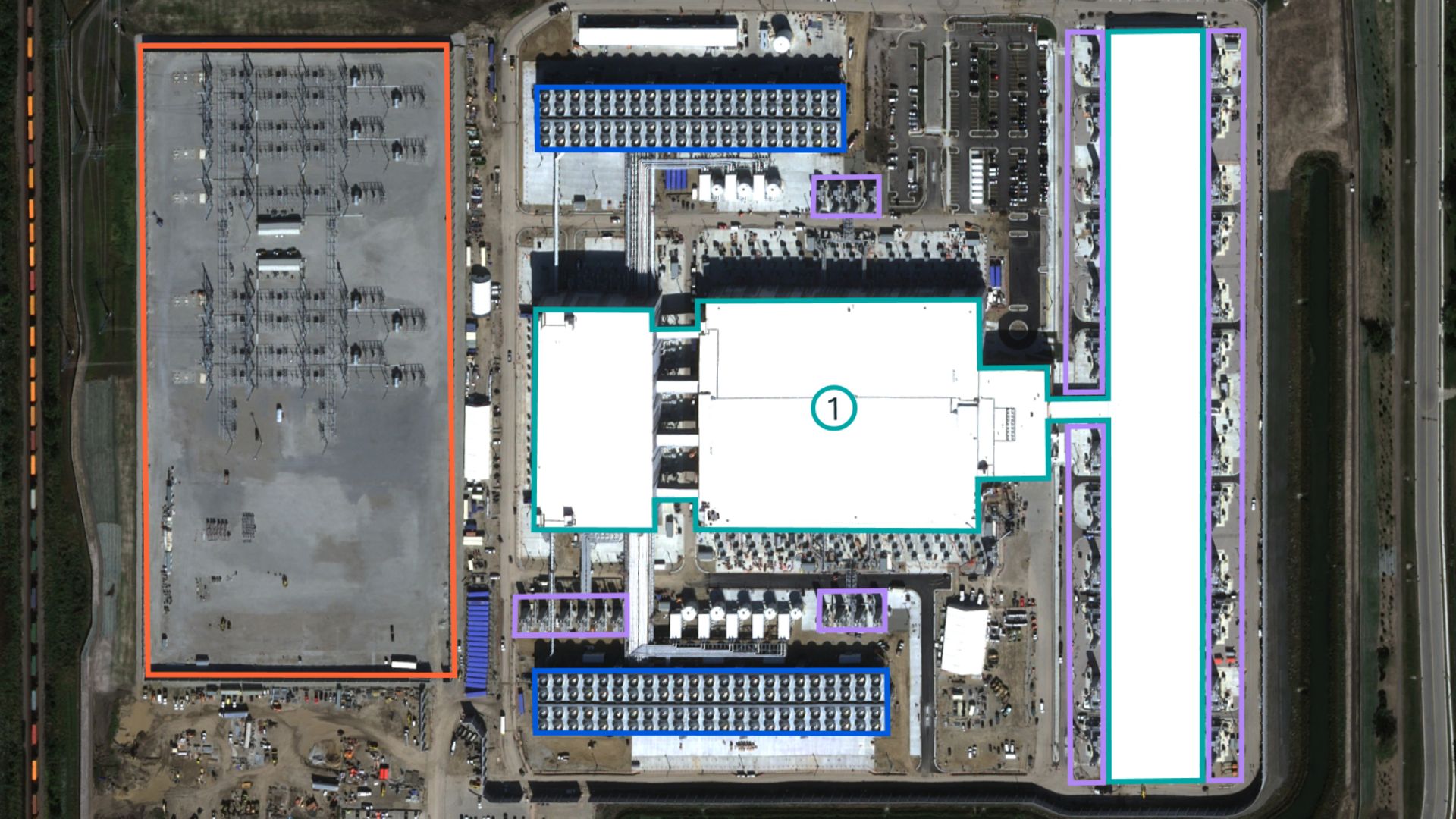

The nonstandard pallet stacker prototype is designed to improve the way goods are handled within warehouses and distribution centers. Traditional pallet stackers often encounter limitations when dealing with nonstandard pallets, which can lead to inefficiencies and increased risk of accidents. By focusing on these challenges, the students crafted a solution that aims to streamline operations while ensuring the safety of workers.

In their design process, the team considered various factors, including load capacity, maneuverability, and ease of use. The result is a prototype that not only meets industry standards but also incorporates innovative features that set it apart from existing models.

The project received positive feedback from Ashley Furniture, which has a vested interest in optimizing its logistics and distribution processes. By investing in student-led initiatives, the company not only fosters new talent but also gains access to fresh ideas that could enhance its operations.

Real-World Applications and Future Prospects

This initiative represents a significant opportunity for the students involved. By collaborating with a major industry player like Ashley Furniture, they gain invaluable experience that can enhance their employability after graduation. The project also highlights the importance of partnerships between educational institutions and businesses, which can lead to mutually beneficial outcomes.

While the current prototype is a step forward, the engineering team envisions further development. Future iterations may incorporate advanced technologies such as automation and robotics, which could further transform material handling in the furniture industry.

Overall, this project exemplifies how academic and commercial collaboration can lead to practical innovations. As the students prepare to graduate, they leave behind a legacy of ingenuity and a prototype that may soon find its way into warehouses, improving operations and setting a new standard for material handling.