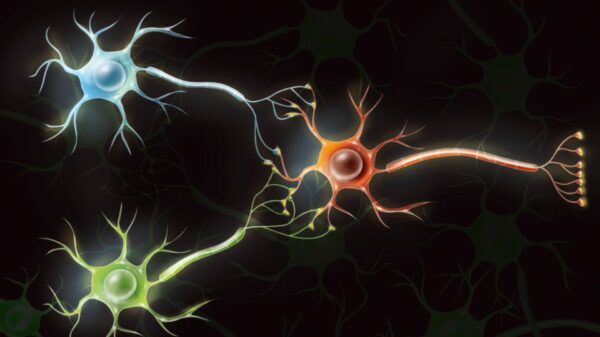

The integration of advanced biomanufacturing processes into clinical settings is evolving, particularly in the realm of autologous cell therapies. Companies and academic centers are increasingly exploring innovative manufacturing models that directly connect patient care with therapeutic production. This approach allows for a streamlined supply chain where the patient plays a crucial role in the treatment process.

Cell therapy manufacturers implement various strategies for autologous therapy production, including point-of-care manufacturing and centralized facilities operated by established biopharmaceutical companies. According to Jason Bock, PhD and CEO of CTMC, while many academic centers possess good manufacturing practice (GMP)-compliant facilities, they often do not meet the rigorous standards required for commercial therapeutics. “None of those [academic] sites go through a pre-approval inspection, which is okay for early clinical stages,” Bock explained, highlighting a significant differentiator in therapeutic development.

Despite the advancements, there are still challenges in maintaining quality control procedures across various academic medical centers. For instance, the validation of methods and standardized testing for autologous CAR T cell production remains inconsistent. Efforts like those from France’s UNITC consortium aim to harmonize these quality standards to enhance the reliability of therapies.

Streamlining Production with Automation

To address existing challenges in the manufacturing of autologous therapies, companies like Sartorius are innovating with automated platforms that promise to enhance production efficiency. A recent paper outlines a system that can reduce per-dose labor costs by 85% and cut facility capital expenses by 50% for autologous therapy production. Additionally, this system is designed to increase throughput by up to 15-fold within a given footprint.

According to Bock, such automation is crucial for speeding up the entire production process, particularly when logistics are carefully coordinated. Each step, from apheresis in the hospital to the final infusion of the product back at the hospital, requires meticulous planning and execution. “Our philosophy is to build industrial-grade manufacturing that is connected to major clinical centers,” Bock said, emphasizing the importance of integrating advanced production techniques with the operational workflows of medical institutions.

CTMC, which originated from the MD Anderson Cancer Center’s Therapeutic Discovery Division in 2022, exemplifies this integrated approach. Situated near the Texas Medical Center (TMC), CTMC operates under a patient-adjacent model that incorporates advanced cell therapy production alongside clinical activities. Earlier this year, CTMC announced a partnership with Syenex to enhance its manufacturing processes by integrating viral vector technology, thereby improving gene delivery and scalability.

Future Prospects in Cell Therapy

The interest in merging advanced biomanufacturing with clinical practices is growing, although Bock cautions against labeling it a definitive trend. “In our hands, cells don’t grow any faster,” he remarked. Instead, the focus is on optimizing interactions and processes that facilitate a quicker transition from research to clinical application. This approach helps manufacturers achieve their value inflection point more efficiently.

As the biomanufacturing landscape continues to evolve, the integration of these technologies holds promise for improving patient outcomes and advancing the field of cell therapy. With ongoing innovations and collaborations, the connection between manufacturing and clinical practice is poised to enhance the delivery of cutting-edge therapies to patients in need.