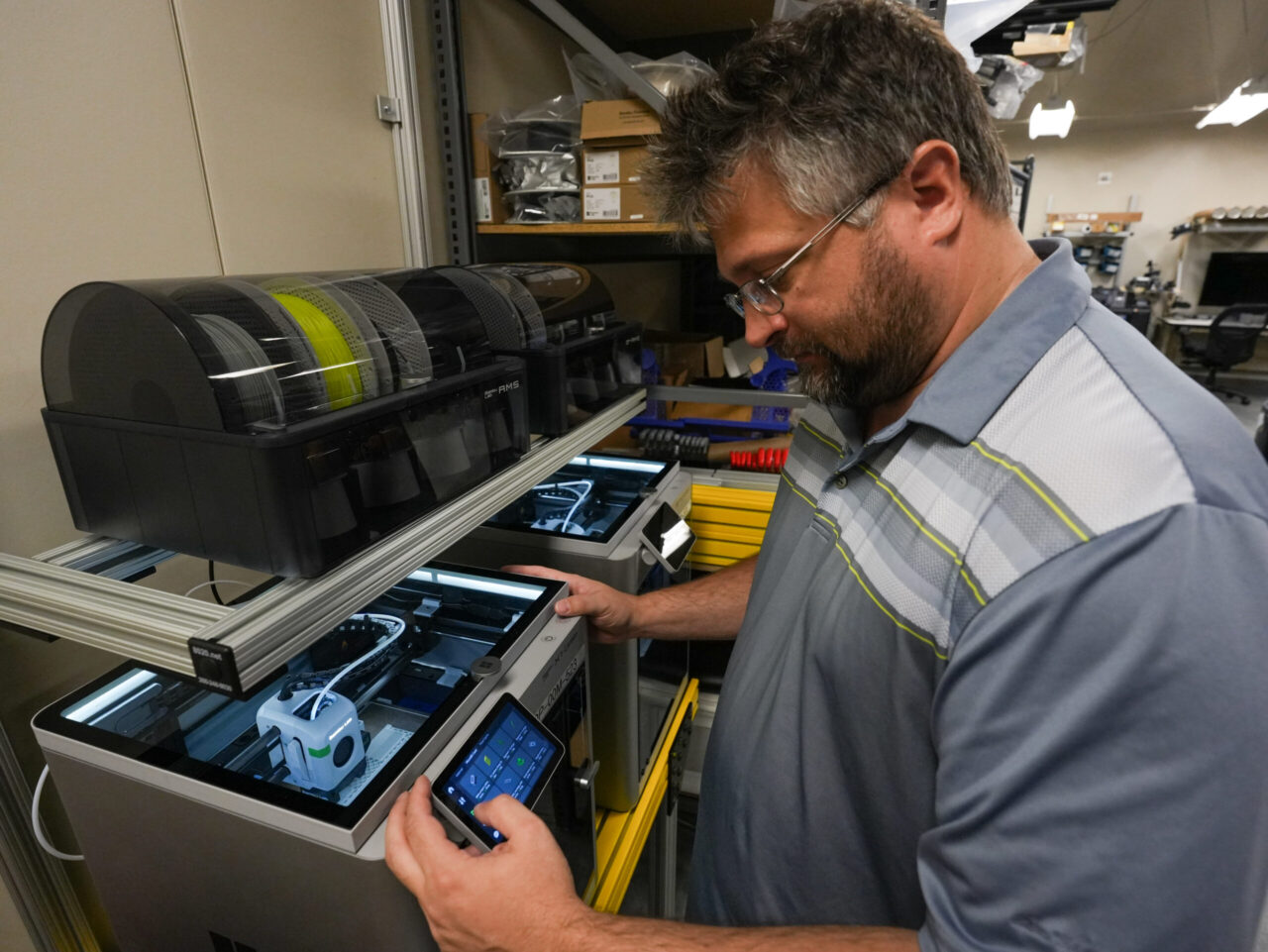

A new facility on the island of Guam aims to significantly enhance the U.S. Navy’s maintenance capabilities through advanced 3D printing technology. The Guam Additive Materials and Manufacturing Accelerator (GAMMA) will address the Navy’s pressing repair needs and streamline logistics within the crucial Indo-Pacific region.

GAMMA will leverage additive manufacturing to produce a wide range of components, from large metal parts to intricate plastic pieces. According to GAMMA director Alex Benham, the facility will empower the Navy to “deploy parts or components as needed, where needed.” With this capability, the Navy can expect to reduce repair times dramatically, addressing a backlog that has plagued maintenance schedules.

The initial contract for the GAMMA facility, awarded to ASTRO America, totals $5 million, with an additional $12 million anticipated. This funding is complemented by support from the nonprofit BlueForge Alliance and the Navy’s Maritime Industrial Base Program Office.

Strategic Importance of Guam

Located in a vital operational theatre, Guam serves as a key logistics base for the Navy, particularly for submarine operations. High-intensity operational schedules necessitate increased maintenance, yet existing capabilities have struggled to keep pace. Repairs that should be routine, such as castings for broken submarine valves, can take anywhere from six months to two years to complete. With GAMMA, that time frame could shrink to just two weeks, allowing for quicker return to service.

As tensions escalate in the Indo-Pacific, maintaining operational availability becomes critical. Prolonged repairs could incapacitate vessels during crucial periods, making facilities like GAMMA strategic assets. Currently, the Navy relies heavily on two submarine tenders for maintenance support in the Western Pacific. GAMMA will provide essential tools and parts for these tenders, significantly reducing both repair times and costs.

Advancements in 3D Printing

The Pentagon is actively investing in 3D printing technologies as part of its broader strategy to enhance military capabilities. Recently, the Defense Logistics Agency awarded $5 billion to six firms to upgrade their shipbuilding capabilities, including the integration of 3D printing. Currently, this technology is used predominantly for “low-risk” parts that do not affect the overall safety of vessels, but it has demonstrated the potential to cut manufacturing times by as much as 80 percent for certain items.

The GAMMA facility seeks to extend these advancements, contributing to the Navy’s force projection efforts. Faster manufacturing and turnaround times will be essential in high-stakes scenarios.

Additionally, GAMMA aims to foster a local talent pipeline in the defense sector. Currently, Guam lacks a mechanical engineering degree program, which ASTRO America plans to establish to support the growing manufacturing capabilities on the island.

While GAMMA is still in the early stages of development, its future expansion will provide crucial maintenance, repair, and manufacturing support to the Navy. By enhancing operational readiness in the Indo-Pacific, GAMMA stands to make a significant impact on U.S. military effectiveness in the region.

As the facility progresses, it will not only bolster the Navy’s capabilities but also contribute to the broader American defense industrial base.