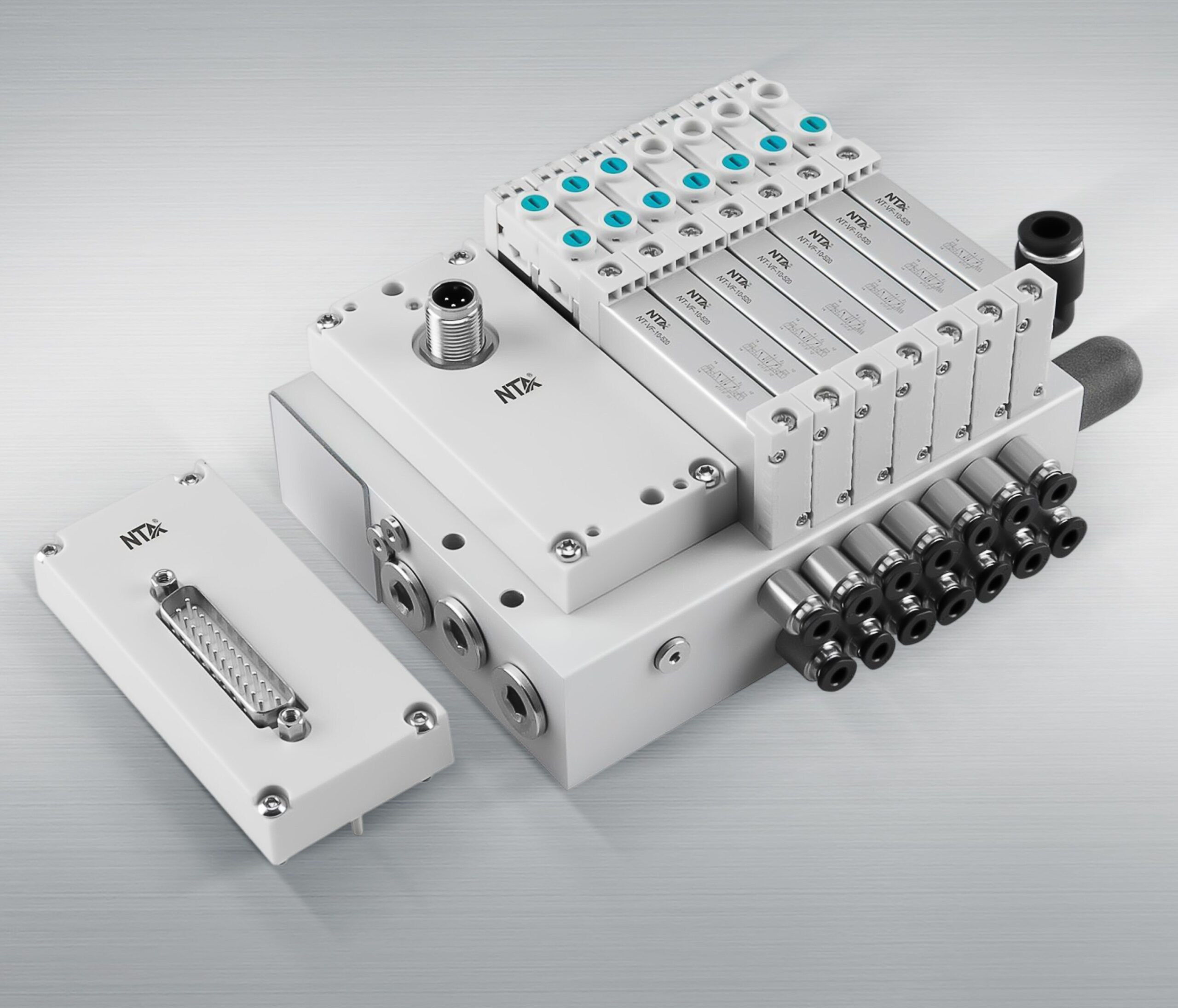

Ningbo Titan Industrial Automation Co., Ltd. (NTA) has launched a new line of energy-efficient pneumatic valves aimed at enhancing speed and sustainability in automated production systems. Announced on January 12, 2026, this innovative product addresses the growing need for manufacturers to reduce energy consumption while maintaining high operational efficiency. As industries face escalating energy costs and stricter environmental regulations, the new valves are positioned as a crucial solution for optimizing pneumatic automation systems.

One of the main challenges in automated production lines has been the inefficiency of standard pneumatic control valves. These traditional valves often suffer from air leaks and high power consumption, particularly in high-frequency applications where rapid direction changes are frequent. NTA’s latest valve design mitigates these issues by re-engineering internal pathways and incorporating coils that operate on significantly less electricity. Customers can anticipate energy savings of up to 30% compared to older models, though actual savings may vary based on system configuration and usage patterns.

Enhancing Speed and Compactness

In the realm of automation, speed is essential. NTA has ensured that its new valves are not only energy-efficient but also engineered for rapid cycling and immediate response. This capability is critical in environments such as fast assembly lines, packaging machines, and robotic handling systems. The compact design of these valves allows for more efficient use of space within control panels, accommodating the trend toward smaller, more integrated equipment without compromising maintenance access.

Moreover, these new valves are designed for compatibility with major industrial networks, including Profinet, EtherCAT, EtherNet/IP, and CC-Link IE Field Basic. This broad protocol support facilitates seamless integration into a variety of automation platforms, making them an appealing choice for original equipment manufacturers (OEMs) targeting diverse global markets.

Robust Applications and Manufacturing Capacity

NTA’s pneumatic valves are suitable for demanding applications across various sectors, including packaging, medical devices, commercial vehicles, and general industrial automation. These valves must meet stringent requirements for high frequency, precision, and reliability, especially in challenging conditions such as extreme temperatures of -40°C and exposure to harsh elements.

With decades of experience in pneumatic component manufacturing, NTA operates extensive production facilities equipped with advanced machining and testing technologies. This infrastructure enables the company to deliver consistent, high-volume output to clients in over 100 countries. NTA adheres to quality standards including ISO 9001:2015 and IATF 16949:2016, ensuring compliance with international safety and environmental regulations.

Mr. Zhu Sijie, Founder of NTA, emphasized the company’s commitment to practical solutions in automation. “Energy efficiency and response speed are no longer optional features—they are baseline expectations in modern automation,” he stated. “Our focus has been on practical improvements that engineers can directly apply in real production environments, rather than experimental concepts that are difficult to implement.”

Looking forward, NTA is set to expand its manufacturing capabilities further with a new 90,000 m² intelligent manufacturing base, scheduled to commence operations in 2026. This expansion is designed to meet the increasing global demand for energy-efficient automation components, ensuring that NTA remains at the forefront of the industry.

As manufacturers around the world prioritize efficiency and reliability, NTA positions itself as a key supplier delivering tangible enhancements in automation technology. The company’s latest valve solutions reflect a dedicated approach to meeting the evolving needs of industrial automation and pneumatic control.